ROQ FIT

• Ideal for M-size printing

• Honeycomb pallets to dissipate temperature

• Agile for small prints

• Narrower pallet arms that allow printing on sleeves

• Compatible with the standard bracket

• Micro registration screen system with vernier scale

ROQ GO

• Up to 150 pieces per hour (White fabric)

• Up to 55 pieces per hour (Dark Fabric)

• Maximum Print Area 500x700mm (20”x28”)

• Professional RIP (ROQSTUDIO powered by NEOSTAMPA)

• Compact machine

• Consistent print quality over larger quantities

• Excellent wash resistance

ROQ HYBRID

- Perfect synchronization with an automatic screen printing machine;

- Intuitive to use;

- High end industrial printheads with recirculation incorporated;

- CMYK or CMYK +2 colours;

- Maximum resolution 600X1200 DPI;

- XL and 2 XL print areas;

- Print height 1 to 6mm;

- Z axis adjustable to the height of the fabric to be printed;

- Uses pigmented ink – ROQ Micropigment;

- Tailored RIP software – ROQ Studio powered by Neostampa.

ROQ READY

- Up to 250 pieces per hour

- Max. pretreatment size 500x700mm / 20”x28”

- Recipes memory

- Compact dimensions

- All included for inline pretreat, flash curing, and heat-pressing

- Robust and industrial equipment

ROQ SAHARA

• Improved energy efficiency and thermal stability through its reinforced insulation

• Standby Mode that allows you to keep your dryer's temperature during breaks at a reduced cost, further improving its energy efficiency

• Increased chamber entry height of 140 mm (5,5’)

• Improved noise reduction

• Axial flow fan for a constant hot-air circulation

ROQBAG

- Piece entrance;

- Piece bagging;

- Automatic cover strip remove;

- Flap fold over;

ROQFOLD

- Folds any kind and/or shape such as: T-shirts (with or without sleeves), sweat shirts, polos (long or short sleeve), trousers, skirts, dresses, etc.

- Quick, accurate, easy to use, economic, safe and efficient.

- Ready to be coupled with ROQ’s automatic packaging line.

- Processing speed of 800 pieces/hour.

- Only one operator needed in the loading station.

ROQLABEL A

- Automatically apply labels to garments;

- Labels up to 80 mm wide;

- Works in conjunction with the ROQFOLD;

ROQPACK

- Designed to pack batches of different types and formats at the same time.

- The packaging length is unlimited.

- The package is done through a flawless plastic welding system.

- Ready to be coupled with ROQ’s automatic packaging line.

- Maximum processing speed of 1200 pieces per hour. When coupled with ROQFOLD it makes an average of 700 pieces per hour.

ROQprint ECO

- Aluminum honeycomb pallets;

- Squeegees with electric movement with ac variator;

- Independent control panel on all print heads;

- Choice of pneumatic screen holder: ”U” clamp or pin system;

- Print head central elevation;

- AC servo-motor rotation system;

- Print heads with high-lift position for quick and easy screen cleaning;

- Central control panel with Polychromatic LCD touch screen (10”);

- Micro registration screen system with vernier scale;

- Individual controls for managing print and flood speed, height, angle of the squeegees and stroke length;

- Placement of the Flash Cure units under the print head.

ROQPRINT NANO

- Aluminum honeycomb pallets;

- Squeegees with pneumatic movement;

- Independent control panel on all print heads;

- Choice of pneumatic screen holder: ”U” clamp or pin system;

- Print head central elevation;

- Frequency drive rotation system for a quick and smooth index;

- Print heads with high-lift position for quick and easy screen cleaning;

- Central control panel with polycromatic LCD touch screen;

- Micro registration screen system with vernier scale;

- Individual controls for managing print and flood speed, height and angle of the squeegees and stroke length.

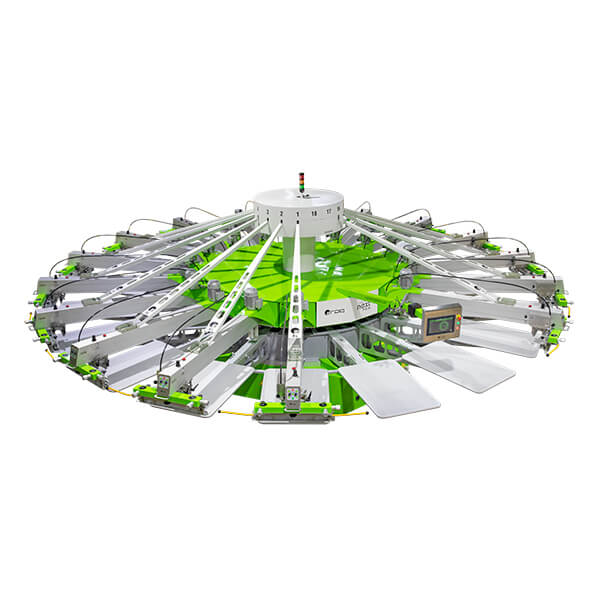

ROQprint NEXT

Aluminum honeycomb pallets;

Squeegees with electric movement with ac variator;

Independent control panel on all print heads;

Choice of pneumatic screen holder: ”U” clamp or pin system;

Print head independent elevation;

AC servo-motor rotation system;

Central control panel with Polychromatic LCD touch screen (10”);

Micro registration screen system with vernier scale;

Individual controls for managing print and flood speed, height and angle of the squeegees and stroke length.

Placement of the Flash Cure units under the print head.