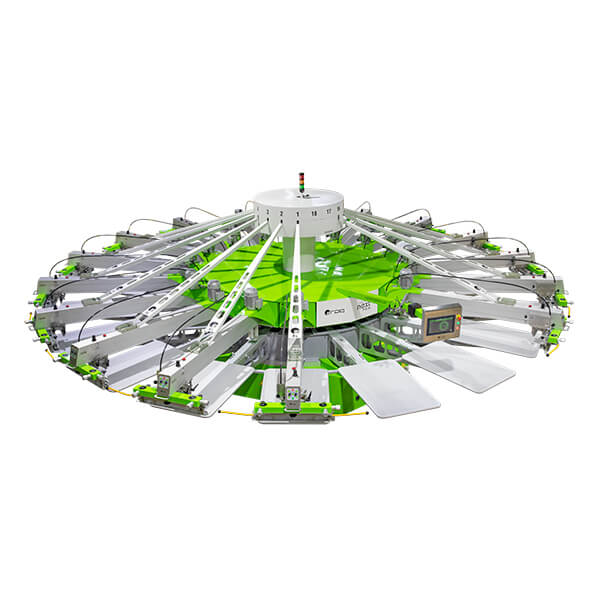

ROQprint OVAL PRO – Oval screen printing machine

15 years ago ROQ decided to do something that no one had been able to create. An oval screen printing machine that hold registration with the same precision as a carousel press. It wasn’t an easy task. For decades several companies had tried and failed. At that time it was the unicorn of automatic screen printing machines.

ROQ was still known by S. Roque and did not had the international projection it has today. Still in the year 2000 the first S. Roque oval screen printing machine rolled out of the factory. In 2015 we revisited this machine (https://www.youtube.com/watch?v=Y-HLsNqnWqc). It is running since day one without any registry problems. In 2000 it developed a flawless rotation system. The oval screen printing machine just won’t lose registry! That is the main difference between ROQ’s oval screen printing machines and the rest of the market.

This is the main factor that makes ROQ the Global Leader in Oval Screen Printing Machines.

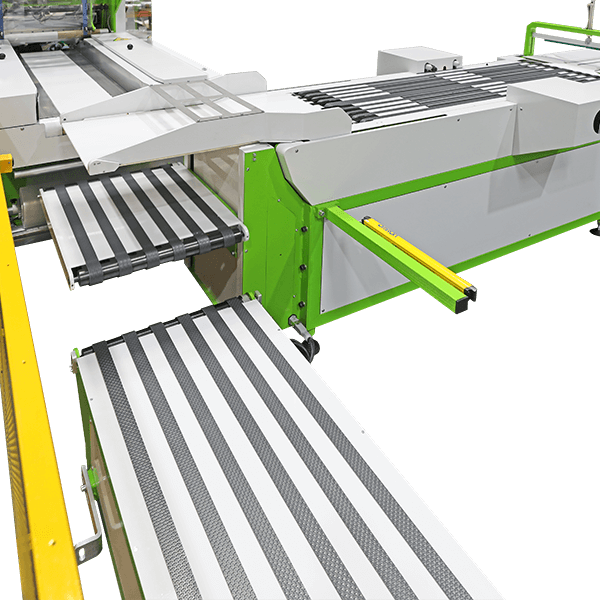

Building the best oval screen printing machine sometimes might not be enough to become the world leader. To achieve leadership in the market ROQ also had to invest its resources in R&D so that the Oval Pro screen printing machine was able to answer every need of a screen printer. So ROQ included all the goodies, the aluminium honeycomb pallets, independent elevation of the print heads and also with high lift position for quick and easy screen cleaning, many control systems and safety features that you can find in HERE.

Any periferic module is connected and synced with the central console including, flash dryers, ROQfoil, ROQflock, etc. This console allows the user to program the entire machine in the most efficient way and in the shortest time possible. This versatility is expanded in the sense that every print head has its own control panel to help during the setup phase.

This leads to the setup times. One of ROQ’s concerns was to guarantee low setup times. The PRU (Positive Registration Unit) was design to help reduce the setup times, but every aspect of this process was taken in account.

So with its low maintenance, short setup times, most of the time the oval screen printing machine will be printing for you and adding value to your company.

Options

- Laser Markers;

- Power and Control Connections for Flash are built into the machine base;

- Flash Cure units;

- Compatible with ROQ FLOCK;

- Compatible with ROQ FOIL;

- Skip Function;

Specifications

| ROQprint OVAL PRO | P16 XL+ | P20 XL+ | P24 XL+ | P28 XL+ | P32 XL+ | P36 XL+ | P38 XL+ | P44 XL+ | P50 XL+ | P56 XL+ |

|---|---|---|---|---|---|---|---|---|---|---|

| Number of Colors (max.) | 20 | |||||||||

| Number of Pallets | 16 | 20 | 24 | 28 | 32 | 36 | 38 | 44 | 50 | 56 |

| Number of Flash Cure connection units (optional) | 6 | 8 | 10 | 12 | 14 | 16 | 17 | 20 | 23 | 26 |

| Maximum Print Size (mm/inch) | 600 X 800 / 20” X 32” | 850×900 / 33”x35” * | |||||||||

| Maximum Screen Size (mm/inch) | 760 X 1150 / 30” X 45” | 1010×1200 / 39”x47” * | |||||||||

| Maximum pallet size (mm/inch) | 650×1050 / 25”x41” | 900×1150 / 35”x45” * | |||||||||

| Maximum Frame Profile / Thickness (mm/inch) | 50×50 / 2”x2” | |||||||||

| Index Precision (mm/inch) | ± 0.025 / 0.001” | |||||||||

| Maximum Production (pieces/h)** | 900 | |||||||||

| Compressed Air Consumption (l/min. 7 bar)*** | 120 l/min | 4.3 cfm + number of each printhead | |||||||||

| Maximum Consumption (kVA)**** | 6.5 | 8.5 | 10 | 11.5 | 13 | 14.5 | 19 | 20.5 | 22 | 23.5 |

| Total Lenght Short (mm/feet) | 7400 / 24.3′ | 9050 / 29.7′ | 10700 / 35.1′ | 12350 / 40.5′ | 14000 / 45.9′ | 15650 / 51.3′ | 16500 / 54.1′ | 18950 / 62.2′ | 21400 / 70.2′ | 23900 / 78.4′ |

| Total Lenght Long (mm/feet) | 8500 / 27.9′ | 10400 / 34.1′ | 12300 / 40.4′ | 14200 / 46.6′ | 16100 / 52.8′ | 18000 / 59.1′ | 19000 / 62.3′ | 21850 / 71.7′ | 24700 / 81.0′ | 27550 / 90.4′ |

| Total Height (mm/feet) | 2230 / 7.38′ | |||||||||

| Minimum Width of the base (mm/feet) | 3950 / 12.11′ | |||||||||

** one squeegee with flooding

*** these values exclude the consumption with flash-curing, they should be calculated separately, taking into account the number and model of the flash cure on the machine.

– Power Supply: 220V, 3x220V, 3x400V – 50Hz or 60Hz.

Reviews

There are no reviews yet.