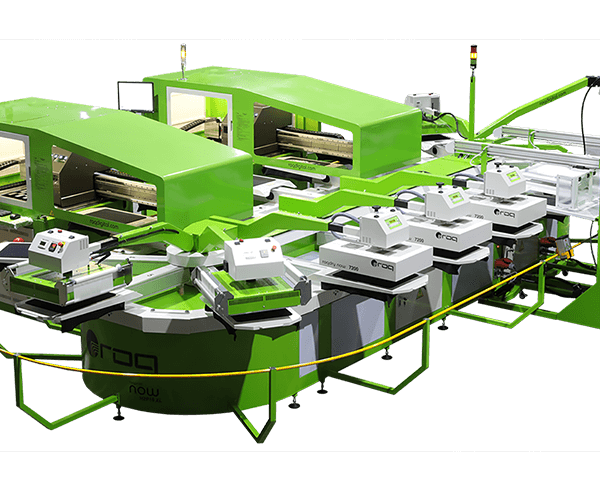

ROQprint NOW is the new DTG platform by ROQ optimized for web to print.

In an era of mass production and fast fashion, Roq is unleashing the RoqPrint Now. Our mission is to help today’s local print shops cater to the ever-increasing and growing world of innovators, creators, and independent designers. The RoqPrint Now facilitates the re-emergence of custom-made printed design by making quick turnaround times and smaller print runs a viable and cost-effective option for the web-to-print market.

The RoqPrint Now is our 100% digital press with no screens required. We’ve combined a digital white station with our digital CMYK station. So now, no matter what color garment you choose, it can be printed digitally. With RoqPrint Now, printers can print completely different jobs in sequence without the downtime of screen and ink changes. Printers will be able to print an unlimited number of shirts, each getting its own unique design one after the other with no downtime in between.

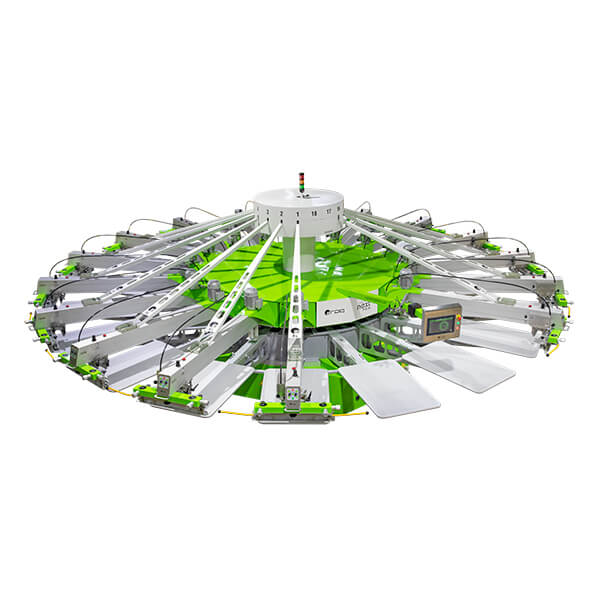

The RoqPrint Now takes DTG printing to the next level. Our RoqPrint Now press features an inline process, which takes the garment from the pre-treatment to the final finishing in one touch. This is a critical innovation in the DTG printing process. Unlike the DTG machines currently on the market, the RoqPrint Now takes a five-station process (pre-treatment, drying, pre-pressing, digital white, and finally CMYK) and rolls it all up into a neat, efficient, and time-saving one-step design.

Now an operator needs only to pick up a garment and scan its barcode to call up the assigned artwork and load it on the press. The RoqPrint Now does the rest.

The RoqPrint Now is an excellent tool for automating workflow, minimizing touches per garment, reducing the risk of human error, and improving profitability. Our proprietary software can be integrated with the print shop’s production management software. Once the user prepares and loads the artwork onto the database, it uses a barcode system to call up the artwork to be printed on an assigned garment. Then, it will queue up the orders and print each file in sequence as garments are loaded on the press.

With RoqPrint Now short-runs become easy and profitable.

This is not all though. Our inline design also allows printers to add a screen print station when necessary. Whether you need to incorporate a discharge base for those zero-hand designs or to include a poly-blocker screen when printing on polyester fabrics, the RoqPrint Now is the press for you. We have created this new solution to both simplify a printer’s workflow as well as allow printers to offer all the services their clients may need.

Specifications

| ROQprint NOW | |

|---|---|

| print stations | 16* |

| maximum print area – mm (in) | 450 x 340 (17.7” x 13.4”) |

| productivity – pieces/hour | 300** |

| pallets type | special pallets with tissue fixing ring |

| RIP software | RoqStudio and RoqServer Special Edition |

| bar code scanner | yes |

| work sequence management software | RoqNowSW |

| electrical requirements | 3x400V AC 50 Hz; 44 kVA; 3ph + N + PE*** |

| compressed air consumption | 0.7 Mpa 120L/min.; 17.6cfm |

| machine dimensions – mm (in) | 7426 x 4987 x 1789 (292” x 196” x 70”) |

| ink type | Aquarius (by Dupont Artistri) |

| operating conditions | (18° C_30° C / 64.4° F_86° F) (humidity: 50%_70%) non-condensing |

| WHITE & CMYK DIGITAL STATION | |

|---|---|

| printheads number | 8+8 |

| printheads type | Fujifilm Dimatix |

| printing height range – mm (in) | 1.5 – 4 mm**** (0.06” – 0.16”) |

| z-axis course | 18 mm |

| resolutions available | 600 x 400 dpi (2 pass) |

| resolutions available | 600 x 800 dpi (4 pass) |

| resolutions available | 600 x 1200 dpi (6 pass) |

| resolutions available | 600 x 1600 dpi (8 pass) |

| printhead recirculation | integrated |

| sub-tanks recirculation | integrated (only White Station) |

| ínk type | pigment |

| operating printing conditions | (18°C_30°C /64.4°F_86°F) (humidity: 50%_70%) non-condensing |

| PRE-TREATMENT STATION | |

|---|---|

| method of deposition/number of nozzles | sprinkler / 2 |

| tank size (L) | 10 |

| pre-treatment deposition | 10 to 50 gr. |

| control method | uni and bidirectional |

| DRY STATION | |

|---|---|

| power | 7.2 kVA |

| power/area | 3.8 (W/cm²) |

| number of heating lamps | 12 x 1200W |

| HEATING STATION | |

|---|---|

| Power | 4kVA |

| power/area | 2 (W/cm²) |

* available for other settings, upon request

** Print size for A4 size

*** power supply type available: 230V, 3x230V, 3x400V in 50/60Hz.

**** as the print distance increases, the definition becomes lower

Reviews

There are no reviews yet.