ROQasp – To keep the work environment clean

At ROQ we create, design and build automatic screen printing machines. Both Oval and carousel. These screen printing machines in average output 1000 pieces per hour. With the same traits across the board, quality, durability, precision and updated with innovations every year. ROQ created a series of modules to complement the screen printing activity. A series of different dryers, a module to foil automatically (the ROQpress Foil) in the middle of the screen printing job a module to flock also in the middle of the screen printing process (the ROQflock). The ROQasp was designed to complement the ROQflock.

Traditional methods of flocking are known for the huge amounts of flocking fibers that contaminate the environment in the print shop. The traditional methods are so intrusive that big areas could became coloured due to the insane amounts of excess of flocking fibers. With the ROQflock this huge problem was eliminated with the added bonus of making it much faster and more profitable.

As ROQ is in the business of automatic screen printing machines, with the emphasis in the automatic, it always looks for ways to make the workflow in a print shop as efficient as possible. After flocking a piece there is always flock fibers that did not adhere to the glue. These will come off easily with the consequence of contaminating the print shop. As the flocking is being done automatically these would lead to a massive amounts of waste around the print shop.

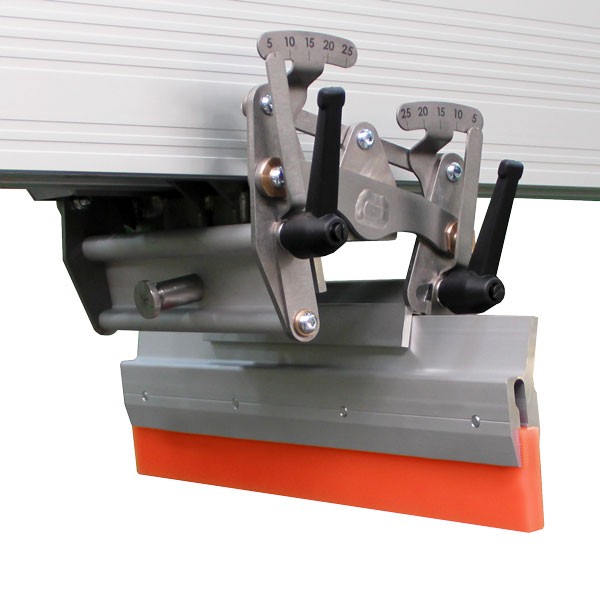

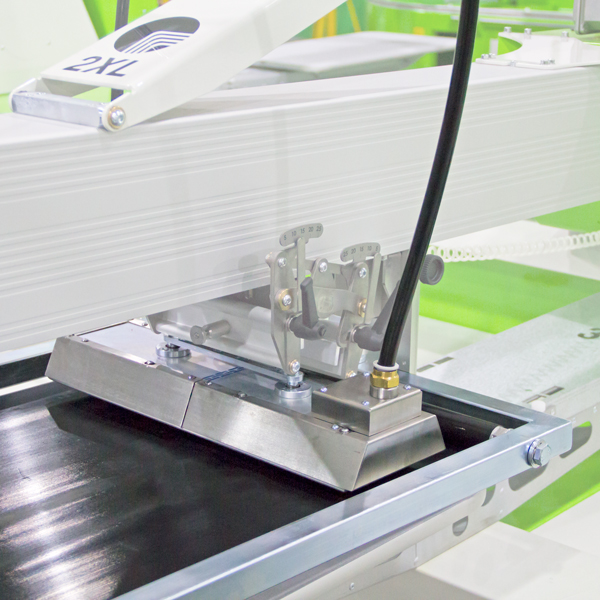

The ROQasp was designed to be installed under any print head and vacuums the excess flock from the jobs done by the ROQflock improving the quality of the final product. It is powered by the automatic screen printing machine to which it is connected. Its vacuum head runs all over the print collecting all the loose fibers into a bag making sure the work environment says clean.

Reviews

There are no reviews yet.